-

로버타그들의 세라믹 베어링은 있습니다 잘 양질이고 값이 싼고 정밀도의. 우리는 수년 동안 협력을 가지고 있습니다.

로버타그들의 세라믹 베어링은 있습니다 잘 양질이고 값이 싼고 정밀도의. 우리는 수년 동안 협력을 가지고 있습니다. -

올가 와인바그이 회사는 수년 동안 세라믹 베어링의 우리의 믿을 만한 전문적 협력, 우리의 펌프가 질<質>에 좋다는 것을 사용되는 그들의 세라믹 베어링입니다.

올가 와인바그이 회사는 수년 동안 세라믹 베어링의 우리의 믿을 만한 전문적 협력, 우리의 펌프가 질<質>에 좋다는 것을 사용되는 그들의 세라믹 베어링입니다.

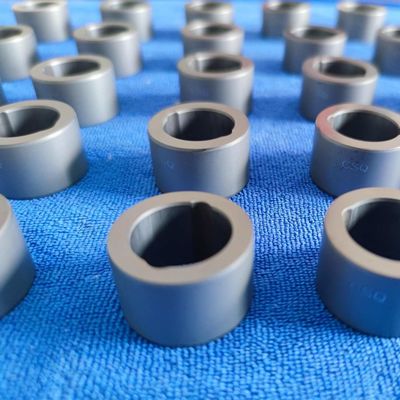

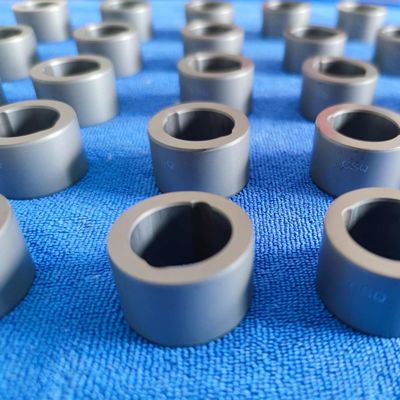

Advanced Ceramic Sleeve For Industrial Applications High Temperature Tolerance And Corrosion Resistance

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 이름 | 주문 제작된 요업 슬라이딩 슬리브 태도 | 분류 | 요업 미끄럼 베어링 |

|---|---|---|---|

| 소재 | 탄화규소 | 크기 | 그림에 따르면, 쿠스토미즈드 |

| 적용 | 펌프 | 패키지 | Foam+Carton은 권투합니다 |

| 품질 | 고 정밀도, 장수, OEM 시라이브 | 사양 | 표준 크기 및 맞춤형 |

| Attribute | Value |

|---|---|

| Name | Customized ceramic sliding sleeve bearing |

| Category | Ceramic sliding bearing |

| Material | Silicon carbide |

| Size | Customized, according to drawings |

| Application | Pumps |

| Package | Foam + carton box |

| Quality | High precision, Long life, OEM service |

| Specification | Standard size and customized |

Custom-engineered silicon carbide (SiC) sliding bearing sleeves represent a cutting-edge solution for demanding industrial, automotive, and aerospace applications. These precision components deliver superior performance compared to conventional steel bearings.

- Exceptional Corrosion Resistance: Silicon carbide's inherent stability ensures outstanding resistance to corrosive chemicals and harsh environments.

- Reduced Friction & Wear: The ultra-smooth, high-hardness surface minimizes friction and wear, enhancing operational efficiency.

- High-Temperature Durability: Maintains structural integrity in extreme heat, perfect for high-temperature applications.

- Max Temperature up to 1650℃

- Low density: 3.15-3.18 g/cm³

- High strength and hardness (2800 HV5)

- Low thermal expansion: 4.0 (10-6/℃)

- High thermal conductivity: 120 W/m°K

- High elastic modulus: 410GPa

- Superior chemical stability, resistance to acid and alkali corrosion

- Higher temperature resistance (up to 1650℃)

- Superior performance in thermal cycling

- Enhanced anti-seizure & anti-jamming properties

- Oil-free operation capability

- Exceptional corrosion resistance

- Electrical insulation & anti-static properties

- Non-magnetic & contamination-resistant

With three factories in China and advanced pressing, sintering, and processing machines, we specialize in customized ceramic bearing solutions. Our company possesses eleven invention patents and has been manufacturing ceramic bearings since 1982.

- Free sample bearings available

- ISO standard compliant production

- In stock bearings for quick delivery

- Small order quantities accepted

- OEM bearing service

- Customized bearing solutions

- Competitive factory pricing

We are a factory in Beijing, China with over 40 years of experience producing ceramic bearings, serving domestic and international clients.

We produce samples before mass production, conduct precise inspections, and use double packaging (foam + carton) to ensure product quality.

As an integrated company with three factories and modern equipment, we offer better delivery times, product quality, and customized solutions.

We cooperate with raw material suppliers to ensure stable quality and pricing. Our customer-focused approach delivers quality products and after-sales service. Contact us to discuss your requirements.